- Reliability Edge Weekly Newsletter by Hamiltonian Systems

- Posts

- Reliability Edge Weekly Reliability Pulse

Reliability Edge Weekly Reliability Pulse

The newsletter for reliability and maintenance engineers and IT leaders, to improve the quality of their asset and MRO data to achieve excellence in manufacturing, published by Hamiltonian Systems. Unified data management & more...

Reliability Edge on the week’s Reliability Pulse keeps you current on data, MRO & AI.

“Small actions are at the heart of Kaizen. By taking steps so tiny that they seem trivial or even laughable, you’ll sail calmly past obstacles that have defeated you before.” — Robert D. Maurer, Ph.D., Author of One Small Step Can Change Your Life: The Kaizen Way

Standardized and Clean Data Collection for Operational Efficiency

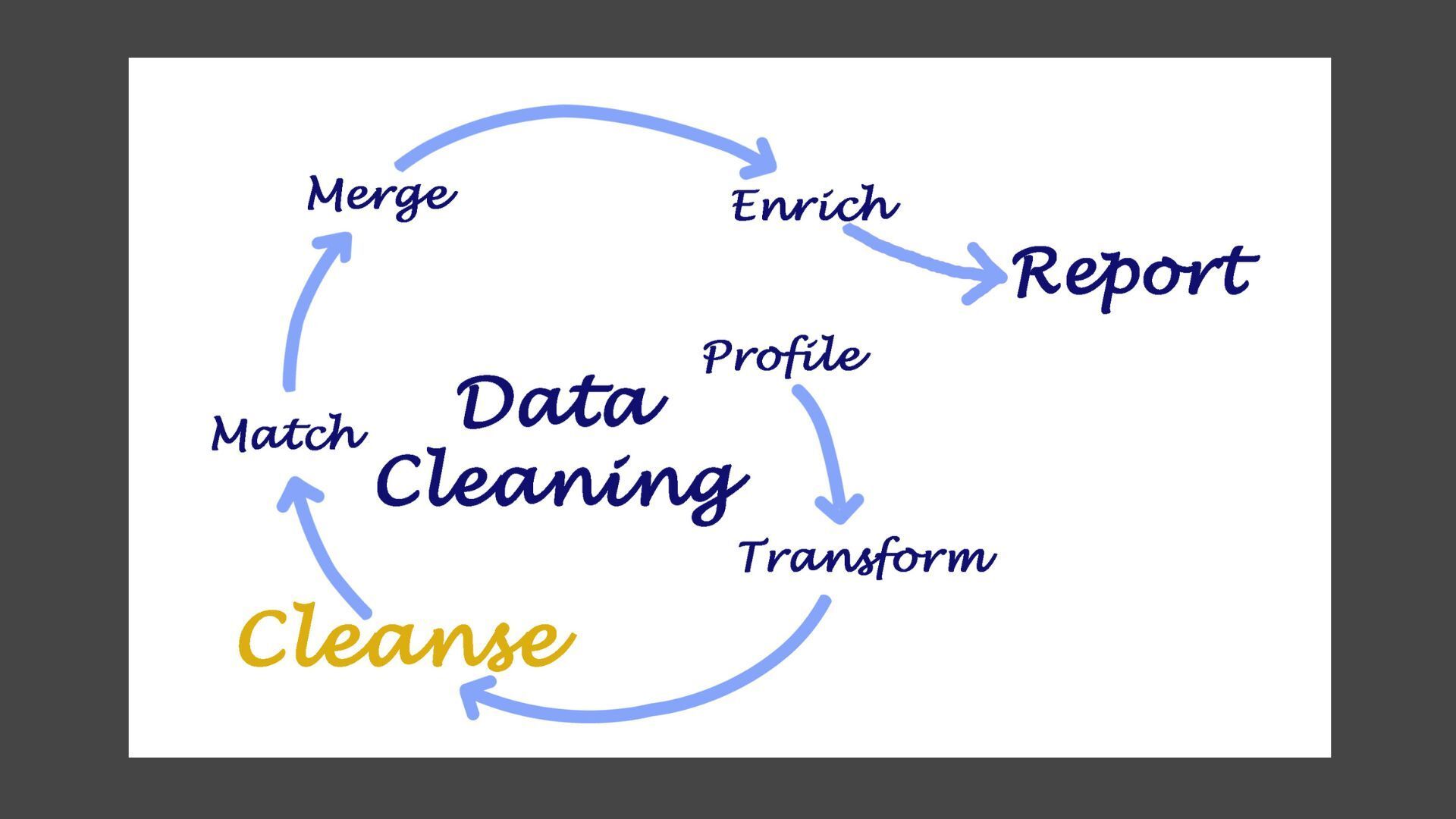

Standardize and Clean Data Collection

Accuracy drives efficiency

In the fast-paced environment of industrial operations, manual data entry is a hidden bottleneck. It’s time-consuming, prone to human error, and often lacks the precision needed for data-driven maintenance planning. By automating data collection, organizations can eliminate these inefficiencies, ensuring accurate, real-time insights that improve resource allocation and operational efficiency.

The problem with manual data capture

Manual data logging may seem manageable, but it introduces significant risks:

Human errors in transcription

Delayed reporting and response times

Inconsistent data formats across teams

Missed early warning signs from asset behavior

If your company is using manual data collection, your data needs to be standardized and cleaned at source using data lifecycle management solutions like Hamiltonian Systems’ Kasei.

In reliability-centered environments, these gaps can lead to misaligned maintenance schedules, unnecessary downtime, and inflated operational costs.

Automated data capture: The efficiency multiplier

Automated data collection through sensors, IoT devices, and integrated CMMS platforms ensures:

Continuous, real-time data flow from critical assets

ML and algorithmic-based data cleansing and enrichment

Error-free measurements that eliminate manual discrepancies

Seamless integration with predictive maintenance systems

Faster, informed decision-making for resource deployment

For example, automating vibration and temperature monitoring allows maintenance teams to act on real anomalies, not subjective walk-around notes.

Resource allocation gets smarter

With reliable data automatically feeding into maintenance planning tools, resource allocation becomes targeted and efficient. Teams can prioritize work orders based on asset condition, risk profiles, and production schedules, ensuring the right tasks are performed at the right time. Inventory management also benefits, as parts ordering aligns with actual equipment needs, not arbitrary timelines.

A foundation for predictive and prescriptive maintenance

Automated data collection is not just about streamlining tasks—it lays the groundwork for predictive analytics and prescriptive maintenance strategies. Clean, accurate data is essential for machine learning algorithms to deliver meaningful insights, driving proactive interventions that prevent failures and optimize uptime.

Conclusion: Automation is operational efficiency in action

The journey to maximizing operational efficiency starts with the basics—accurate data. By automating data collection, organizations remove manual roadblocks and unlock a smarter, faster approach to maintenance and resource management.

References

Mobley, R. K. (2020). An introduction to predictive maintenance (2nd ed.). Butterworth-Heinemann.

U.S. Department of Energy. (2023). Operations & maintenance best practices guide (Release 4.0).

Imai, M. (2012). Gemba Kaizen: A commonsense approach to a continuous improvement strategy (2nd ed.). McGraw-Hill.

Smart Inventory Automation for Cost Savings

Smart Inventory Automation for Cost Savings

Balancing availability with efficiency

In reliability-driven operations, managing spare parts inventory is a constant challenge. Overstocks tie up capital and warehouse space, while stockouts risk unplanned downtime and delayed repairs. Smart inventory automation bridges this gap, using real-time data and predictive analytics to ensure parts are available when needed, without inflating inventory carrying costs.

The hidden costs of traditional inventory management

Manual or reactive inventory practices often lead to:

Overstocking non-critical parts results in excess carrying costs

Stockouts of essential components, increasing downtime risks

Inefficient procurement cycles, driven by guesswork rather than actual demand

Limited visibility into parts consumption trends

These inefficiencies silently drain operational budgets and reduce maintenance responsiveness.

How smart inventory automation works

Modern automated inventory systems leverage:

Real-time integration with CMMS and EAM platforms

Sensor-driven consumption tracking

Risk-based predictive analytics for demand forecasting

Automated replenishment workflows linked to supplier networks

With these tools, inventory levels are continuously optimized based on usage patterns, lead times, and asset criticality, ensuring that teams have the right part at the right time, without costly overstocking.

From reactive to proactive inventory strategies

Automated systems provide:

✅ Dynamic minimum and maximum stock levels

✅ Alerts for critical parts approaching reorder thresholds

✅ Data-driven purchasing aligned with production schedules

✅ Insights into supplier performance management and consolidation

By automating inventory control, organizations transition from reactive purchasing to a proactive, data-informed strategy, improving both efficiency and reliability.

Boosting uptime and reducing working capital

The financial impact is twofold:

Lower inventory carrying costs through optimized stock levels

Reduced downtime risk by ensuring critical parts availability during unexpected repairs

Smart inventory automation aligns MRO management with operational needs, delivering significant cost savings without compromising maintenance effectiveness.

Conclusion: Automation is the key to inventory efficiency

For reliability teams, smart inventory automation is no longer a luxury, it’s a competitive necessity. It delivers the balance every operation needs: lean inventory costs with robust parts availability for critical maintenance tasks.

References

Mobley, R. K. (2020). An introduction to predictive maintenance (2nd ed.). Butterworth-Heinemann.

U.S. Department of Energy. (2023). Operations & maintenance best practices guide (Release 4.0).

Imai, M. (2012). Gemba Kaizen: A commonsense approach to a continuous improvement strategy (2nd ed.). McGraw-Hill.

Intelligent Automation for Maintenance Scheduling

Intelligent Automation for Maintenance Scheduling

Using real-time (daily) data for smarter priorities

In maintenance, “real-time” doesn’t always mean second-by-second monitoring. For most plants, it’s about daily data collection, reporting, and trend analysis that enables smarter scheduling decisions. Unfortunately, many organizations still rely on static, time-based maintenance schedules that don’t reflect what’s happening on the ground. The result? Over-servicing healthy assets and under-reacting to emerging risks.

Static schedules cause inefficiency

Fixed-interval maintenance plans often create two types of waste:

Unnecessary work orders for assets showing no signs of wear

Missed warning signs on equipment trending toward failure

Without daily insights into asset condition, maintenance teams are left guessing which tasks are truly urgent.

How intelligent scheduling automation works

Modern platforms integrate with CMMS, EAM, and IoT systems to automate task prioritization by:

Collecting daily equipment health data (vibration, temperature, runtime)

Analyzing historical failure patterns

Weighing asset risk level and criticality within operations

Balancing workforce and material availability

These advanced algorithms continuously re-prioritize tasks, ensuring critical interventions happen promptly, while deferring non-essential work to maximize efficiency.

Key benefits of intelligent maintenance scheduling

✅ Reduces unnecessary interventions

✅ Optimizes resource allocation (labor, parts, time)

✅ Improves uptime and asset lifespan

✅ Aligns maintenance with production schedules

For example, if daily vibration readings flag a pump’s performance drift, the system can escalate its work order, ensuring proactive repair. Meanwhile, non-critical tasks are rescheduled without manual re-planning chaos.

From firefighting to flow-based scheduling

With intelligent automation, maintenance becomes condition-based, not calendar-based. Teams shift from reactive workflows to a streamlined process that dynamically adjusts to real-world asset needs.

Conclusion: Data-driven scheduling is operational efficiency in action

By automating maintenance scheduling based on daily data insights, reliability teams eliminate wasteful tasks, focus resources where they matter, and boost operational uptime. Efficiency is no longer about working harder; it’s about scheduling smarter.

References

Mobley, R. K. (2020). An introduction to predictive maintenance (2nd ed.). Butterworth-Heinemann.

U.S. Department of Energy. (2023). Operations & maintenance best practices guide (Release 4.0).

Imai, M. (2012). Gemba Kaizen: A commonsense approach to a continuous improvement strategy (2nd ed.). McGraw-Hill.

Please answer a brief question and we will share the insights in next week.

From last week, the week of July 29th, on what would most improve your plant’s reliability today: there was a three-way tie between a CMMS that actually reflects reality, a leadership team that believes in proactive maintenance, and asset data that doesn’t look like it came from a ransom note.

What’s your organization’s biggest barrier to implementing predictive/prescriptive maintenance at scale? |

Real-world ridiculousness (or close enough) from the front lines of reliability

“We’ve Always Done It This Way” Meets Data-Driven Reality

A reliability manager recently shared how their old maintenance schedule was so rigid, the team could set their watches by when they'd be overhauling equipment that wasn’t even running.

After automating task priorities using daily asset data, the first report flagged a piece of equipment the team had forgotten they owned. It hadn’t been on a single PM schedule… because it had been running perfectly for 3 years.

The new mantra became: “If we don’t see its data, we don’t see its problems.”

This newsletter provides best practices, strategies, techniques, insights and data from our ongoing research in short, concise articles.

By incorporating these tips and techniques into your routine, you can cultivate a operations that flourish throughout the year.

Until next time!